Adapters for sharpening of small drill bits

These adapters extend the BSG 220’s range to cover 1.5 – 3mm. One each adapter for sizes 1.5 – 1.6 – 2 – 2.4 – 2.5 and 3mm. Neatly packed in a wooden box with sliding lid.

BSG 220 Adapters for sharpening

Quick ViewAdapters for sharpening of small drill bits

These adapters extend the BSG 220’s range to cover 1.5 - 3mm. One each adapter for sizes 1.5 - 1.6 - 2 - 2.4 - 2.5 and 3mm. Neatly packed in a wooden box with sliding lid.

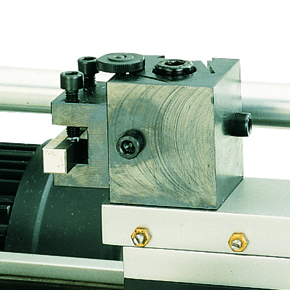

Die-cast aluminium compound table KT 150

With precision milled dovetail slides, thus also suitable for metal work. For routing, milling, slotting of steel, non-ferrous metals, plastics and wood.

Characteristics:

- Each slide provided with locking screws.

- With re-adjustable dovetail guides to eliminate play.

- Feed adjustment by means of 2 handwheels with graduated, zero-adjustable dials (1 revolution = 2mm feed, 1 graduation = 0.05mm feed). Plane-milled table.

- Three continuous MICROMOT standard T-slots (12 x 6 x 5mm).

- Fence with predrilled positioning holes, fastening screws.

- A practical screw clamp used when routing.

- Table 200 x 200mm. Maximum travel 150 x 150mm. Overall height 75mm. Weight 4.9kg.

Compound Table KT 150

Quick ViewDie-cast aluminium compound table KT 150

With precision milled dovetail slides, thus also suitable for metal work. For routing, milling, slotting of steel, non-ferrous metals, plastics and wood.

Characteristics:

- Each slide provided with locking screws.

- With re-adjustable dovetail guides to eliminate play.

- Feed adjustment by means of 2 handwheels with graduated, zero-adjustable dials (1 revolution = 2mm feed, 1 graduation = 0.05mm feed). Plane-milled table.

- Three continuous MICROMOT standard T-slots (12 x 6 x 5mm).

- Fence with predrilled positioning holes, fastening screws.

- A practical screw clamp used when routing.

- Table 200 x 200mm. Maximum travel 150 x 150mm. Overall height 75mm. Weight 4.9kg.

Die holder for round dies.

For threads M 3 – 4 – 5 – 6 – 8 and 10. With holder Ø 10mm for mounting in the tailstock drill chuck of the lathe. The holder is held by hand while cutting the threads. Neatly packed in wooden box with sliding lid.

Die holder for round dies

Quick ViewDie holder for round dies.

For threads M 3 - 4 - 5 - 6 - 8 and 10. With holder Ø 10mm for mounting in the tailstock drill chuck of the lathe. The holder is held by hand while cutting the threads. Neatly packed in wooden box with sliding lid.

Edge finder set

Used for fast and accurate location of starting point of work pieces with respect to the machine spindle on milling machines. Size 6 x 6 x 50mm and 6 x 5 x 75mm. Comes in wooden box with sliding lid.

Edge finder set

Quick ViewEdge finder set

Used for fast and accurate location of starting point of work pieces with respect to the machine spindle on milling machines. Size 6 x 6 x 50mm and 6 x 5 x 75mm. Comes in wooden box with sliding lid.

4-jaw-chuck, self-centering for FD 150/E

Used to clamp cylindrical, square or octagonal work pieces. High accuracy. Clamping range with reversible jaws from 1 – 20mm (inside) and 20 – 50mm (outside). Ø 50mm.

FD 150/E 4-jaw chuck with independent jaws

Quick View4-jaw-chuck, self-centering for FD 150/E

Used to clamp cylindrical, square or octagonal work pieces. High accuracy. Clamping range with reversible jaws from 1 - 20mm (inside) and 20 - 50mm (outside). Ø 50mm.

FD 150/E Chip collecting tray with splash guard

Of 1.5mm thick sheet steel, powder-coated. Bevelled edges at the front and back enable easy cleaning. Pre-drilled mounting holes for the secure stability of the FD 150/E. L 400 x W 165 x H 140mm. The lathe depicted here is not included in the scope of delivery.

FD 150/E Chip collecting tray with splash guard

Quick ViewFD 150/E Chip collecting tray with splash guard

Of 1.5mm thick sheet steel, powder-coated. Bevelled edges at the front and back enable easy cleaning. Pre-drilled mounting holes for the secure stability of the FD 150/E. L 400 x W 165 x H 140mm. The lathe depicted here is not included in the scope of delivery.

Multiple range standard ER 11 type collets

Offering high concentricity. May be reduced up to 0.5mm below their nominal diameter (intermediate sizes not required). D = 11.5mm, L = 18mm. One each of 2 – 2.5 – 3 – 4 – 5 – 6 and 7mm are included. With clamping nut M 16 x 1. Suitable for the main spindle of the FD 150/E. Supplied in a wooden box.

FD 150/E Collets

Quick ViewMultiple range standard ER 11 type collets

Offering high concentricity. May be reduced up to 0.5mm below their nominal diameter (intermediate sizes not required). D = 11.5mm, L = 18mm. One each of 2 - 2.5 - 3 - 4 - 5 - 6 and 7mm are included. With clamping nut M 16 x 1. Suitable for the main spindle of the FD 150/E. Supplied in a wooden box.

FD150/E Drill Chuck

Capacity 0.5 – 6.5mm. Industrial quality with high concentricity (allowed up to 10,000rpm). Complete with arbour B 10 x MK 0/short. For the tailstock of the FD 150/E.

FD 150/E Drill Chuck

Quick ViewFD150/E Drill Chuck

Capacity 0.5 - 6.5mm. Industrial quality with high concentricity (allowed up to 10,000rpm). Complete with arbour B 10 x MK 0/short. For the tailstock of the FD 150/E.

14-piece parallel supports set

Ground in pairs. For adjusting work on drilling machines, lathes and milling machines. Made of high-alloy, hardened steel (58 – 62 HRC). Parallel accuracy 0.02mm. 2 each of 8 x 10, 15, 20, 25, 30, 35 and 40mm. Length 100mm. Packed in a wooden box.

FD 150/E PD 250/E, PD 400 14-piece parallel supports set

Quick View14-piece parallel supports set

Ground in pairs. For adjusting work on drilling machines, lathes and milling machines. Made of high-alloy, hardened steel (58 - 62 HRC). Parallel accuracy 0.02mm. 2 each of 8 x 10, 15, 20, 25, 30, 35 and 40mm. Length 100mm. Packed in a wooden box.

PD 400 Radius Cutting Attachment

Is mounted on the cross slide in place of the tool holder. For producing convex and concave shapes, for turning radii or 3/4 spheres with radii of 32mm max. Height adjustable tool holder (boring tool tip adjustable from 30 through 45mm above cross slide) for use with FD 150/E, PD 250/E, PD 400 and older PROXXON lathes. Dimensions: base plate 67 x 50mm, height 55mm. Including finishing cutter 8 x 8 x 80mm. In wooden box with sliding lid.

FD 150/E PD 250/E, PD 400 Radius Cutting Attachment

Quick ViewPD 400 Radius Cutting Attachment

Is mounted on the cross slide in place of the tool holder. For producing convex and concave shapes, for turning radii or 3/4 spheres with radii of 32mm max. Height adjustable tool holder (boring tool tip adjustable from 30 through 45mm above cross slide) for use with FD 150/E, PD 250/E, PD 400 and older PROXXON lathes. Dimensions: base plate 67 x 50mm, height 55mm. Including finishing cutter 8 x 8 x 80mm. In wooden box with sliding lid.

6-piece turning tool set. Made of high-quality cobalt HSS steel. Ground.

One each boring, roughing out, parting, finishing, right and left cutter. Size 6 x 6 x 65mm. For FD 150/E, supplied in wooden box

FD 150/E Turning Set

Quick ViewTool holder for rotary tools.

For use on lathe machines. Made of steel with standard 20mm MICROMOT collar size. For precise clamping of rotary tool IBS/E or LBS/E in the tool post of the lathe. Shaft 8 x 10mm. Total length 65mm.

FD 150/E, PD 250/E and PD 400 Tool holder for Rotary Tools

Quick ViewFive piece collet set (not depicted)

Includes 1 each of 2.4 – 3 – 3.2 – 4 and 5mm, for milling cutters. Supplied in a wooden box with sliding lid.

FF 230 and PF 230 Collet Set

Quick ViewFive piece collet set (not depicted)

Includes 1 each of 2.4 - 3 - 3.2 - 4 and 5mm, for milling cutters. Supplied in a wooden box with sliding lid.

Of solid aluminium (surface-compacted). With two step motors for the axes X (transverse) and Y (lengthwise). Table size and travel distances, see description of MF 70/CNC-ready above.

MF 70/CNC-Ready Micro Compound Table

Quick ViewMill/drill system BFW 40/E

Mill/drill system BFW 40/E, with controller for speeds of 900 – 6,000rpm.

Characteristics:

- The triple ball bearing armature provides direct drive (no gearing).

- Die-cast aluminium head with spindle neck of 43mm (European standard).

- Large, easy to use switch with emergency function. Chart indicates optimum speeds for milling and drilling of various materials.

- The motor operates at 40V, supplied from the power pack/ controller. At this level, the control characteristics are ideal and yield high torque, even at lower speeds. (The compound table, drill stand and step clamps are not included.)

Mill/drill system BFW 40/E

Quick ViewMill/drill system BFW 40/E

Mill/drill system BFW 40/E, with controller for speeds of 900 - 6,000rpm.

Characteristics:

- The triple ball bearing armature provides direct drive (no gearing).

- Die-cast aluminium head with spindle neck of 43mm (European standard).

- Large, easy to use switch with emergency function. Chart indicates optimum speeds for milling and drilling of various materials.

- The motor operates at 40V, supplied from the power pack/ controller. At this level, the control characteristics are ideal and yield high torque, even at lower speeds. (The compound table, drill stand and step clamps are not included.)

Mill/drill unit BFB 2000

For standard drills with 43mm spindle neck.

Characteristics:

- Head tilts through 90°, thus offering a multitude of capabilities: Diagonal drilling, versatile milling without need of special milling bits, milling of diagonal slots.

- Fine feed selectable allowing fine head feed for milling. With dial and depth scale.

- Geared rack and pinion feed for effortless drilling.

- 45mm diameter drill column, 500mm long. Approx. 140mm throat (column outside to tool centre). 65mm stroke.

- Plane-milled, solid base plate approx. 200 x 200mm with two continuous MICROMOT standard T-slots (12 x 6 x 5mm).

- Easy clamping of all common drills with standard 43mm spindle collar.

- Weight approx. 6.5kg.

Mill/drill unit BFB 2000

Quick ViewMill/drill unit BFB 2000

For standard drills with 43mm spindle neck.

Characteristics:

- Head tilts through 90°, thus offering a multitude of capabilities: Diagonal drilling, versatile milling without need of special milling bits, milling of diagonal slots.

- Fine feed selectable allowing fine head feed for milling. With dial and depth scale.

- Geared rack and pinion feed for effortless drilling.

- 45mm diameter drill column, 500mm long. Approx. 140mm throat (column outside to tool centre). 65mm stroke.

- Plane-milled, solid base plate approx. 200 x 200mm with two continuous MICROMOT standard T-slots (12 x 6 x 5mm).

- Easy clamping of all common drills with standard 43mm spindle collar.

- Weight approx. 6.5kg.

PD 230/E, PD 250/E and PD 400 HSS boring tool Set (6 pieces)

One each cutter for 60 degree (metric) and 55 degree (Whitworth) inside threads, 1.3mm – 2.65mm and 4mm. Shaft of Ø 6mm. Length 95mm. The cutters are held by a tool holder (9 x 9mm) that mounts to the tool post of either PD 230/E, PD 250/E or PD 400. Comes in wooden box with sliding lid.

PD 230/E, PD 250/E and PD 400 HSS boring tool Set (6 pieces)

Quick ViewPD 230/E, PD 250/E and PD 400 HSS boring tool Set (6 pieces)

One each cutter for 60 degree (metric) and 55 degree (Whitworth) inside threads, 1.3mm - 2.65mm and 4mm. Shaft of Ø 6mm. Length 95mm. The cutters are held by a tool holder (9 x 9mm) that mounts to the tool post of either PD 230/E, PD 250/E or PD 400. Comes in wooden box with sliding lid.

To be used with the quick change tool post for PD 250/E.

PD 250/E Additional quick change tool holder (separately)

Quick ViewPD 250/E 4-Jaw Chuck with Independent Jaws

For clamping angular and asymmetrically shaped work pieces. Capacity up to 80mm. Chuck Ø 75mm.

PD 250/E 4-Jaw Chuck with Independent Jaws

Quick ViewPD 250/E 4-Jaw Chuck with Independent Jaws

For clamping angular and asymmetrically shaped work pieces. Capacity up to 80mm. Chuck Ø 75mm.

Precision V-blocks. Used to clamp various work pieces.

Made from hardened steel, precision ground in pairs. Four different depths of prism incisions V, all at 90°. Size 50 x 30 x 30mm. The solid clamp and knurled knob ensure superb securing of the workpiece. Supplied in a wooden box with sliding lid.

PD 250/E and PD 400 Precision V-blocks

Quick ViewPD 250/E and PD 400 Tungsten disposable tips (not depicted)

For the holders as described above.

PD 250/E and PD 400 Tungsten disposable tips (not depicted)

Quick ViewPD 250/E and PD 400 Tungsten disposable tips (not depicted)

For the holders as described above.

Centre turning attachment. For highest accuracy with high rotational precision.

This includes: 1 face plate, 2 fixed centres (MK 2 and MK 1/short) and 1 drive dog. Packed in a wooden box.

PD 250/E Centre turning attachment

Quick ViewCentre turning attachment. For highest accuracy with high rotational precision.

This includes: 1 face plate, 2 fixed centres (MK 2 and MK 1/short) and 1 drive dog. Packed in a wooden box.

PD 250/E Chip collecting tray with splash guard

Made from 1.5mm thick sheet metal, powder coated. Bevelled edges at the front and back allow slight clean-ing. Mounting hole and raised base to secure lathe are pre-drilled. L 550 x W 240 x H 160mm. The depicted lathe is not included in the offer.

PD 250/E Chip collecting tray with splash guard

Quick ViewPD 250/E Chip collecting tray with splash guard

Made from 1.5mm thick sheet metal, powder coated. Bevelled edges at the front and back allow slight clean-ing. Mounting hole and raised base to secure lathe are pre-drilled. L 550 x W 240 x H 160mm. The depicted lathe is not included in the offer.

Collet set with ER 20 collets: For extreme true concentric accuracy. 2 – 10mm.

For high precision machining of round parts. The collet set is mounted instead of the lathe chuck. With 8 collets (2 – 2.5 – 3 – 4 – 5 – 6 – 8 and 10mm). Packed in a wooden box.

PD 250/E Collets

Quick ViewCollet set with ER 20 collets: For extreme true concentric accuracy. 2 - 10mm.

For high precision machining of round parts. The collet set is mounted instead of the lathe chuck. With 8 collets (2 - 2.5 - 3 - 4 - 5 - 6 - 8 and 10mm). Packed in a wooden box.

PD 230/E and PD 250/E Cutter set with tungsten inserts

Three holders (90mm long): for roughing out; for longitudinal work; for 90mm boring bar, holes from 12mm.

Standard tungsten inserts, 55°, plated (commercially available version). Three additional inserts securing screw and key TX 8 are included. 8 x 8mm.

PD 250/E Cutter set with tungsten inserts

Quick ViewPD 230/E and PD 250/E Cutter set with tungsten inserts

Three holders (90mm long): for roughing out; for longitudinal work; for 90mm boring bar, holes from 12mm.

Standard tungsten inserts, 55°, plated (commercially available version). Three additional inserts securing screw and key TX 8 are included. 8 x 8mm.

PD 230/E and PD 250/E Five Piece Set

One each roughing out, parting, finishing cut, left and right cutter. Comes in wooden box with sliding lid. 8 x 8 x 80mm

PD 250/E Five Piece Set

Quick ViewPD 230/E and PD 250/E Five Piece Set

One each roughing out, parting, finishing cut, left and right cutter. Comes in wooden box with sliding lid. 8 x 8 x 80mm

PD 250/E Fixed steady for longer work pieces

Especially for boring. Also required if the tailstock cannot be used to ”counter”. Up to Ø 40mm.

PD 250/E Fixed steady for longer work pieces

Quick ViewUsed in the PD 250/E quickchange system. Used to part stock and cut slots. The 12 x 3 x 85mm HSS tool contains cobalt.

PD 250/E Parting Tool for the Tool Holder

Quick ViewUsed in the PD 250/E quickchange system. Used to part stock and cut slots. The 12 x 3 x 85mm HSS tool contains cobalt.

PD 250/E Parting Tool Holder

Quick ViewUsed in the PD 250/E quickchange system. Used to part stock and cut slots. The 12 x 3 x 85mm HSS tool contains cobalt.

Professional gear chuck with MK 1

For the tailstock of the PD 250/E. Capacity up to 10mm.

PD 250/E Professional gear chuck with MK 1

Quick ViewProfessional gear chuck with MK 1

For the tailstock of the PD 250/E. Capacity up to 10mm.

PD 250/E Quick change tool post

Easy to use. For quick tool change and easy height adjustment. Includes 2 tool holder elements.

PD 250/E Quick change tool post

Quick ViewPD 250/E Self-centering 3-jaw chuck

Suitable for PD 250/E and the dividing attachment. Identical to PD/250 E chuck but with 3 jaws instead of 4. High quality clamping fixture as per DIN 8386, Class 1, concentricity accuracy 0.04mm. Capacity through reversing jaws from 2 – 90mm.

PD 250/E Self-centering 3-jaw chuck

Quick ViewPD 250/E Three piece thread cutting set

One cutter for external thread (ground to 60°, metric) one for internal thread, one general cutting. Comes in wooden box with sliding lid. 8 x 8 x 80mm.

PD 250/E Three piece thread cutting set

Quick ViewPD 250/E Three piece thread cutting set

One cutter for external thread (ground to 60°, metric) one for internal thread, one general cutting. Comes in wooden box with sliding lid. 8 x 8 x 80mm.

PD 400 Self-centering 3-jaw chuck

Identical to the lathe chuck of lathe PD 400. Capacity through reversing chucks 3 – 100mm.

PD 400 3-jaw chuck Self-centering

Quick ViewPD 400 Self-centering 3-jaw chuck

Identical to the lathe chuck of lathe PD 400. Capacity through reversing chucks 3 - 100mm.

PD 400 4 Jaw Chuck with Independent Jaws

Used to mount irregularly and asymmetrically shaped objects. Each jaw is adjusted individually and centering is thus achieved manually. Hardened, reversible jaws. Chuck diameter 100mm

PD 400 4 Jaw Chuck Independent Jaws

Quick ViewPD 400 4 Jaw Chuck with Independent Jaws

Used to mount irregularly and asymmetrically shaped objects. Each jaw is adjusted individually and centering is thus achieved manually. Hardened, reversible jaws. Chuck diameter 100mm

PD 400 4 Jaw Chuck with Independent Jaws

Used to mount irregularly and asymmetrically shaped objects. Each jaw is adjusted individually and centering is thus achieved manually. Hardened, reversible jaws. Chuck diameter 100mm.

PD 400 4 Jaw Chuck with Independent Jaws

Quick ViewPD 400 4 Jaw Chuck with Independent Jaws

Used to mount irregularly and asymmetrically shaped objects. Each jaw is adjusted individually and centering is thus achieved manually. Hardened, reversible jaws. Chuck diameter 100mm.

To be used with the quick change tool post for PD 250/E.

PD 400 Additional quick change tool holder (separately)

Quick ViewTo be used with the quick change tool post for PD 250/E.

PD 400 Center Turning Accessory

Ideal when turning with highest possible accuracy. Supplied with 2 dead centres (MK2 and MK3), drive/ face plate with 30mm bore as well as reducing bushes 30/20mm and 30/15mm. A threaded drive pin screws into the headstock flange and the drive plate

PD 400 Center Turning Accessory

Quick ViewPD 400 Center Turning Accessory

Ideal when turning with highest possible accuracy. Supplied with 2 dead centres (MK2 and MK3), drive/ face plate with 30mm bore as well as reducing bushes 30/20mm and 30/15mm. A threaded drive pin screws into the headstock flange and the drive plate

PD 400 Collet attachment with collets

For accurate use on round components. One hardened collet each hardened collet 2 – 3 – 4 – 5 – 6 – 8 – 10 – 12 and 14mm are included. Concentric accuracy better than 0.02mm, much better than a chuck. One soft collet for making a custom size yourself. The included collet attachment is mounted in the place of the headstock chuck. Supplied in a wooden box.

PD 400 Collet attachment with collets

Quick ViewPD 400 Collet attachment with collets

For accurate use on round components. One hardened collet each hardened collet 2 - 3 - 4 - 5 - 6 - 8 - 10 - 12 and 14mm are included. Concentric accuracy better than 0.02mm, much better than a chuck. One soft collet for making a custom size yourself. The included collet attachment is mounted in the place of the headstock chuck. Supplied in a wooden box.

PD 400 Collet Attachment with Collets

For accurate use on round components. One hardened collet each hardened collet 2 – 3 – 4 – 5 – 6 – 8 – 10 – 12 and 14mm are included. Concentric accuracy better than 0.02mm, much better than a chuck. One soft collet for making a custom size yourself. The included collet attachment is mounted in the place of the headstock chuck. Supplied in a wooden box.

PD 400 Collet Attachment with Collets

Quick ViewPD 400 Collet Attachment with Collets

For accurate use on round components. One hardened collet each hardened collet 2 - 3 - 4 - 5 - 6 - 8 - 10 - 12 and 14mm are included. Concentric accuracy better than 0.02mm, much better than a chuck. One soft collet for making a custom size yourself. The included collet attachment is mounted in the place of the headstock chuck. Supplied in a wooden box.